Oil Pump Problems

These Japanese super cars had a common problem that would often lead to the self-destruction of the motor. The Achilles Heel of the Skyline RB26 motor is the oil pump, I personally caught this issue on my own Second GTR (Build Story) leading me to replace it with a new one . This wasn't a problem on all Skylines, only the GTR's made between 1989 and 1991, after 1991 Nissan fixed the issue. Most people will tell you the problem is the width of the drive on the oil pump gears, they say the engagement area is too small, while that may be true (by appearance), it also isn't the 100% exactly correct answer...

|

| Broken Oil Pump Gears |

The real problem is on the nose of the crank, the clearance between the nose of the crank and the part that drives the oil pump inner gear was too loose. The inner circumference of the oil pump inner drive gear was actually too much larger than the outer total circumference of the crank nose. The extra play had no effect on the motor at low RPM, but at high RPM the harmonic engine vibrations would often prove fatal for the oil pump, usually resulting in absolutely shattered pump gears.

This was emphasized as the main problem further by the fact that the biggest risk of failure always came at high RPM and on the rev limiter, it was the full throttle pull followed by the ignition cut on the rev limiter that would result in the leading edge of the drive slamming into the top side of the pump gear, this repeated hammering (even though the swing length was only measurable in fractions of a millimeter) is what leads to the shattering of the gears. Early signs of this could sometimes rarely be seen by a vigilant driver with a keen eye on the oil pressure gauge. If you notice your oil pressure is constantly low, you may need to Pull The Engine, follow this Guide on Engine Removal.

|

| Nissan Oil Pump Screws Loose and Backing Out |

The net effect of the hammering on the drive gears, was that, some of the Philip's head screws that hold the back-plate of the oil pump on, would back themselves out of their screw holes... to the point that oil would leak out of the pressurized part of the pump and right back into the sump, resulting in minimal oil flow through out the block. Over time this would cause engine failure too, just significantly slower then the instantaneous boom and seizure from oil starvation, usually caused by the broken drive gears. Although it was rare to catch this in time, an accurate oil pressure gauge can go a long way. Hard evidence of this is provided in the next following sections.

At the end of last summer I started to notice my oil pressure was low, meaning it would not go above 2.5 bar even at 7,000 rpm... so after doing my research I realized it was the classic sign of oil pump failure, the slow kind, that has the backing plate coming loose, not the usual catastrophic type. After removing the engine, my concerns were justified, and the issue surrounding oil pump failure was very clear.

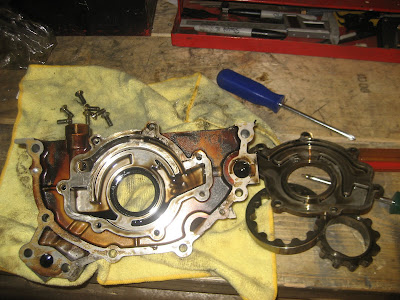

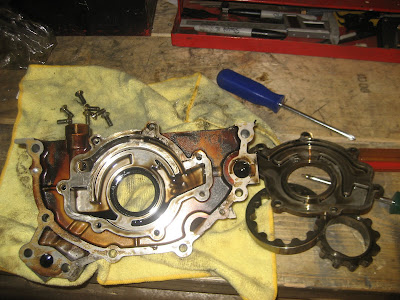

What we discovered once the oil pump was out

. I'ts pretty clear what happened here... all the encrusted burnt on oil on the pump housing says a lot about the situation...

The reason for the oil leaking through and my horrendously low oil pressure... 2 of the screws on the backing plate had backed themselves out of their holes, and 2 other screws were merely finger tight...

The reason for the oil leaking through and my horrendously low oil pressure... 2 of the screws on the backing plate had backed themselves out of their holes, and 2 other screws were merely finger tight...

A look inside the pump itself shows a rather worn out situation - this is precisely why you want to make sure you know as much as possible about the oil situation when considering buying a used car, take a look at our Guide and Checklist for Second Hand Car Buyers

A look inside the pump itself shows a rather worn out situation - this is precisely why you want to make sure you know as much as possible about the oil situation when considering buying a used car, take a look at our Guide and Checklist for Second Hand Car Buyers

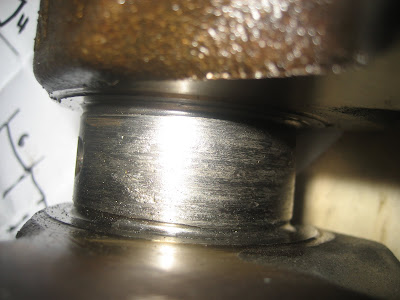

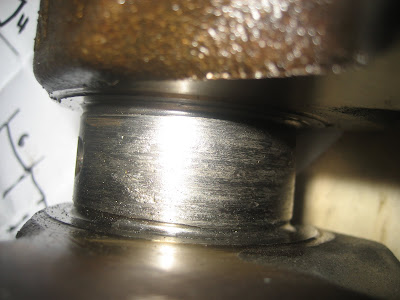

Here's the reason those screws had come loose. The engagement area between the crank and the oil pump gear is only about 4 mm, and there's a lot of play between the pump and the crank... so at high rpm these things are prone to explode, or in my case vibrate themselves apart. It's very obvious to see the the indentation on the engagement area, that small dent on the crank and gear are evidence of the aforementioned "hammering effect".

Here's the reason those screws had come loose. The engagement area between the crank and the oil pump gear is only about 4 mm, and there's a lot of play between the pump and the crank... so at high rpm these things are prone to explode, or in my case vibrate themselves apart. It's very obvious to see the the indentation on the engagement area, that small dent on the crank and gear are evidence of the aforementioned "hammering effect".

We then look to the crank and bearings to tell the other half of the story. When the crank does not receive enough oil to properly

We then look to the crank and bearings to tell the other half of the story. When the crank does not receive enough oil to properly lubricate

the journals, due to the fact that, the majority of the oil is being leaked before it can be pumped, the crank journals and bearings will wear out, and show signs of scratching, rough surfaces and heat marks. All of these symptoms can lead to bearing failure, which means the end of a running motor.

If we look closely at the individual

If we look closely at the individual journals

, the # 1 rod journal shows score marks...

... and the # 6 rod journal showed major scratches and excessive heat. Attention now on the bearings themselves, the problem becomes even more apparent.

... and the # 6 rod journal showed major scratches and excessive heat. Attention now on the bearings themselves, the problem becomes even more apparent.

Heat and rough surfaces on a number of these shells, tells us that things were on their way to getting bad. There's a REALLY good write up on How to Assemble the RB26 Engine where they go into detail about bearing installation tips and tricks.

Heat and rough surfaces on a number of these shells, tells us that things were on their way to getting bad. There's a REALLY good write up on How to Assemble the RB26 Engine where they go into detail about bearing installation tips and tricks.

This one in particular showed some really excessive heat. It's clear that, the protective coating usually on each bearing has worn away. It wouldn't have been much longer before this bearing let go.

This one in particular showed some really excessive heat. It's clear that, the protective coating usually on each bearing has worn away. It wouldn't have been much longer before this bearing let go.

This outlines the real problem with the RB26 oil pump in a basic nutshell.

More Details now... First up, basic Specs:

Stock: 47 L/min @ 6000 RPM

Nismo: Nismo claims comparable output to Stock but uses stronger gears.

HKS: 53 L/min @ 6000 RPM (Old Pump, Jun style)

HKS: ?? L/min @ 6000 RPM (New Pump, Tomei style)

Tomei: 57 L/min @ 6000 RPM

JUN: 59 L/min @ 6000 RPM (Calculated using Jun's Claim of +25% of OEM)

Trust: 59 L/min @ 6000 RPM

Reimax: 70 L/min @ 6000 RPM

(originally posted on GTR PWR: Post by Allan JD74)

As a result of many forum based discussions and many broken oil pumps from various manufacturers, the user: TryingToBeBest (GTRcanada) has put together a whole bunch of additional information gathered from all over the world, here is what he had to say about oil pumps:

|

| Here is the pictures of my pump, its amazing how they crack even on the long sleeved crank collar! |

I bought a used oil pump, order a crank collar (from Australia dealer) and a Reimax gearset directly from Japan!

Here is my findings:

#1 - Outside diameter of the N1 pump is ~77mm, the STD is ~81mm, they do looks like they made from very different materials! I do not have any dots on the used STD pump gears (like on the N1) that i bought from the guy on this forum! I would dream to have the gears already replaced with performance, but im still pretty shure they are stock!

N1 Has 11 tooth and the STD has 12!

#2 - The collar from australia, the guy is telling me that he copy the actual JUN collar and i do belive him. It looks like a very qality product, BUT it is very wobbly in the standard oil pump and even more wobbly in the REIMAX oil pump gearset. Here is some pics:

Side clearance on the standard pump is .013 one side and .010 on the other so ~.011 - .012, comes to a ~.006 each side. I think this is crazy large!

So if i measure clearance the same way on the Reimax gearset, this numbers are growin even higher! .018 and .016, so comes to a ~.008 each side. OMG.

Reimax gearset is ~81mm outside diameter but it similar to a profile of an N1 pump. I guess they make that to lower the cost of the product, the inside gear stays the same and the outside (internal gear) is slightly larger(STD) or smaller (N1) depending on the application! But Reimax gear looks very very nice!

#3 - And in the end I just would like to say what if Nissan production would rotate the oil pump gear half tooth eather way, than the common breaking point would be MUCH MUCH stronger. But this is just my personnal opinion, and it would probably worked only on STD pump gear with 12 teeth! (in RED - common breaking point)

I received a collar from Allen (jdms13rhd) and all i can say is that im very very pleased and impressed with quality, craftmenship and clearances of the collar!

I also received second STD oil pump to doble verify all of the findings!

Here is the beginning, you can see Caliber676's oil pump (he said around 60k km) and GTRBrian's pump (He stated around 80k km was on his)

Here is the first pump (~60k km), as you can see .0015" and .0025", so around 0.002" each side. Even though that Allen was promising ~.001 each side i think, by the feeling of collar going in and out of the pump inner gear, it almost feels like TOO LITTLE CLEARANCE!!! And when the collar is going to be pressed on, its going to stretch a little, making the clearances even more tighter!)

Here is the Reimax set! As i was saying before the gear is larger than stock so, here is the specs on it: 0.007" and 0.009" which comes roughly around .008; much much better than my stock R33 crank!

And in the end, here is another stock pump with ~80k km, as you can see clearances are very very tight! .002 and .0025" so ~ .002 each side which = very very good!

If you guys can see there is a clear image of the old short collar, the part of the drive where tche collar was not touching is like new, so i can say that my measurmens are practically identical to the new pumps!

In the end I would like to thank Allan for doing his research on this problem, ask him to use even more stronger metal in the feauture, if it is possible of course (in order to be bulletproof on international market) andrecommend him to decrease inner diameter of the collar by .012 - .025". This, in my opinion will make collar a bit thicker and increase the thickness of the hard working flat spots of collar which make them a little bit stronger.

Thank you Allen

So here is another update withe the measurements of my ~R33 crank! They are not looking very good!

Firs is stock pump gear! .014 and .013 comes to an average ~ .006" on each side - even more than with australian collar! THIS IS CRAZY

Now with Reimax gears - .019 and .018 SO - ~.009 each side! No matter what metal this would be made of they will brake soon or later with this wobble!

In the end i would like to state my opinion, because i see sometimes people are saying that there should be a clearance, if Nissan engeneers did it so there should be one! I would like to say that Nissan almost missed the oil pump with theirs early short oil pump drives, and in the "upgraded" drive they only band aid this problem extending the drive, so no they didn't pay enough attention in that area and the clearances there should be much smaller than what we experiencing right here!

Even GReddy pumps can explode:

|

| Broken GReddy Oil Pump |

If you're doing an engine removal because of

Oil Pump Problems it could also be good timing to Overhaul the rest of the Engine Components, take a look at this

Guide on Complete Engine Block and Head External Overhaul and Turbo Swap.

Comments

agreed stock gear is very weak.

agreed don't bounce off rev or staging limiters.

if it causes problems with oil pump imagine what other engine parts are stressed.

scratch on crank it's a big deal.

I think tight clearance causes problems. higher rpms require more clearance.

Now take in to account that a metal will expand when used and heated .

So i doubt the "COLD" Clearances taken above will have any thing to do with operating clearances when the crank is at a elevated temp.

So flywheel and use of the clutch system will add temps to the crank through latent heat transfer.

Then we have engine oil running through the crank at a temp of roughly 80 Degree C maybe even more on a track.

So why not heat the crank to 80 Degrees C and check the clearance with the oil pump then and see .

I think the oil pumps rate of expansion on the inner gear at 80 Degrees C will be alot less then the crank shafts rate of expansion.

In theory i might have a point but i have never tried it in real life so i cant comment.

But everything must have a clearance hot and cold.

And if you dont do that you might cause more harm then good??

Camshafts and Valves have a hot a cold clearance ?

Let me know what you think ?

If anyone is willing to do it! email us through the contact page and I'ill be more than happy to include works!

The alloy housing on the other hand grows a lot faster at a rate of around 23.3*10^-6 per degree. The pump housing to gears gets more loose with increased temp. You can calculate it exactly by measuring the outer pump gear diameter and thickness, and multiplying it by the aluminium expansion coefficent and the number of degrees changed from ambient.

I am inclined to think that the N1 pumps fail more frequently in rebuilt motors due to people using clearences on the crank mains that are too loose for that pump design. This combined with the crank whip effect (twisting and bending due to forces being applied, and harmonics)cause the pump gear and front housing to carry crank load forces that it was never designed to run. This is in part proven when I ask you "when was the last time you heard of a factory built vspec 2 nur, or R34 N1 Rb26 having this problem".

Yes of course, limitor bashing is definatly also a contributing factor.

Big main and rod clearences are needed on powerful engines in order to maintain a thicker oil film and cooler bearing journals.

Factory main bearing maximum oil clearence is 1.8 thou. Big power engines typically run 2.2 minimum and up to 3. Drag and circuit can be as big as 4 thou.

Basically if you run your mains over 2.2 thou then you should use a tomei 3 piece pump or an external belt driven pump.

I would expect more damage to the oil pumps with less clearance, as the crankshaft has to move around, especially when people are hitting the rev limiters, or over-revving.

If the Nissan Engineers thought these oil pumps needed more clearance, they would have built that into their N1 Crankshafts.

I just want to confirm this before buying! Thanks!

So I have an RB26 R32. Is it OK to just change the Oil pump to a N1 oil pump?

I'm looking at a car at the moment and am in a strange situation where the best I can work out the car was built IN February 1993. Tim M has said here that the oil pump issue was fixed AFTER February but I would just like to clarify this. The car has a chassis number starting with 300 and when I look at a picture published on another source it looks like there was a change in model in February as that's when the chassis codes changed. If someone could have a look and confirm on this it would be much appreciated.

http://www.gtrusablog.com/2013/01/nissan-skyline-gt-r-r32-production-dates.html

Post a Comment